our proprietary non-melting scalable multiple-material ultrasonic AM (SMAM)

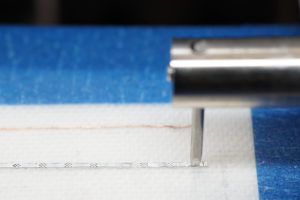

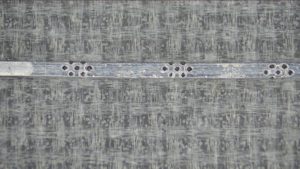

SMAM enables the building of an object or voxels with various materials (metals/thermoplastics/polymers). As seen in the picture, we can bond to pure copper as a wire form (or strip) on polymers such as fiberglass (fire retardant, FR4), glass-reinforced epoxy resin composite (GRE), carbon fiber reinforced polymers (CFRP), and high-performance thermoplastics.

New PCB AM (patent pending)

Non-ink-based, solid-copper electrical traces (or pattern/wiring) additively-manufactured on FR4 class material by using SMAM additively to print electrical circuits on a surface; a copper wire (or strip) is used as feedstock for electric traces/patterns.

Multiple materials am

A new additive building capability in 3D in various materials such as metals (even aerospace-grade metals Al6061/7075/titanium) and polymers using SMAM; is especially useful for metallic structures.

As unique advantages, SMAM may create an integral surface cladding of graded-Z materials (Ta, Ti, tin, steel, Cu, Al, etc.) as radiation shielding around a specific component or a PCB.